- 您现在的位置:买卖IC网 > Sheet目录19076 > 91319-2 (TE Connectivity)10 ROW RECPT SEAT TOOL

!

i

Seating Tools 91318-- [ ], 91319-- [ ], and 91320-- [ ]

3.2. Application Tooling

Power for the seating tool must be provided by a

machine capable of supplying a downward force of

89 Newtons (N) [20 lb] per contact. Manual Electric

Servo Press (MEP 6T) 2--1399500--5 and Bench Top

Electric Servo Presses (BMEP 3T) 1--1399400--5 and

(BMEP 5T) 2--1399401--4 are available for this

seating tool. For information on the presses, visit the

press--fit assembly equipment website at

http://tooling.tycoelectronics.com/pressfit.asp .

4. SEATING

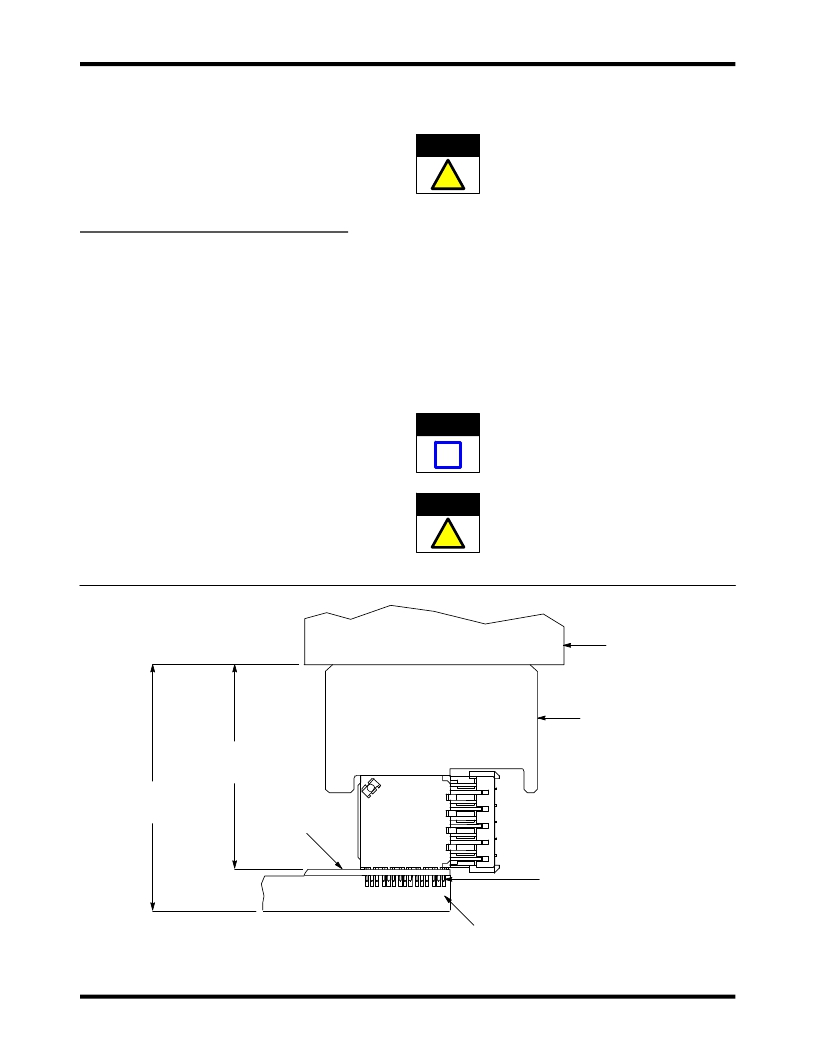

1. Set seating height to the dimension shown in

Figure 2 (applicator shut height will equal the

seating height PLUS the combined thicknesses of

the pc board, and pc board support fixture).

2. Position the connector onto the pc board so that

the contacts are properly aligned with the holes in

the pc board and the holes or slots in the pc board

support fixture. See Figure 2.

3. Sit the connector onto the pc board until the tips

of the contacts are resting securely on, but have

not fully entered, the holes in the pc board.

408-- 4571

meets the seating tool. Verify the alignment of the

pc board support fixture, pc board, connector, and

seating tool.

CAUTION Damage to the pc board, seating tool, or

connector may occur if seating height is

improperly set, if the pc board is not properly

positioned with the seating tool, or if the seating

tool is not properly seated on the connector

before cycling the applicator ram.

6. Cycle the applicator ram according to

instructions for the application tooling.

7. Remove the pc board with the seated connector,

and check the connector for proper seating

according to the following:

a. the widest section of each contact is inside its

intended pc board hole

b. the connector is seated on the pc board with

the seating height given in Figure 2.

NOTE For detailed inspection requirements of the

seated connector assembly, refer to Application

Specification 114--13020.

4. Position the seating tool onto the connector with

the slanted surface oriented as shown in Figure 2.

5. Center the seating tool and connector under the

applicator ram, and slowly lower the ram until it just

CAUTION

!

A damage connector should not be used. If a

damaged connector is evident, it should be

removed from the pc board and replaced with a

new one.

View After Seating

Applicator Ram

(Fully Down)

Applicator

Shut Height

(Ram Down)

Seating Height

(Connector Seated)

38.1 [1.50]

PC Board

Figure 2

Seating Tool Centered

Under Applicator Ram and

Bottomed on Connector

Contacts in PC Board Holes

and Holes or Grooves in

PC Board Support Fixture

PC Board Support Fixture

(Customer Supplied)

2 of 3

Tyco Electronics Corporation

Rev A

发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

P51-200-G-O-P-5V-000-000

SENSOR 200PSI 7/16-20UNF 2B 1-5V

P51-100-G-O-P-5V-000-000

SENSOR 100PSI 7/16-20UNF 2B 1-5V

ASA-40.000MHZ-L-T

OSC 40.000 MHZ 3.3V SMD

553-0322

LED 3MM 5V GREEN

78C06RAT

SWITCH DIP RAISE SLIDE 6POS

P51-750-S-Y-P-5V-000-000

SENSOR 750PSIS 7/16 5V

P51-75-G-O-P-5V-000-000

SENSOR 75PSI 7/16-20UNF 2B 1-5V

P51-50-G-O-P-5V-000-000

SENSOR 50PSI 7/16-20UNF 2B 1-5V

相关代理商/技术参数

91319-3

功能描述:手工工具 10R RECPT SEAT TOOL

RoHS:否 制造商:Molex 产品:Extraction Tools 类型: 描述/功能:Extraction tool

913-194

制造商:SPC Multicomp 功能描述:CAPACITOR 47UF 63V

913-195

功能描述:支架与垫片 Plastic Spcr .195 in Nylon White RoHS:否 制造商:Schurter 类型:Transipillar Spacers 长度:16 m 螺纹大小:M4 外径:10 mm 材料:Nylon with Steel 电镀:Zinc

9131-9573-003

制造商:AEP 功能描述:

9131B

功能描述:DC POWER SUPPLY 30V/6A 5V/3A 制造商:b&k precision 系列:9130B 零件状态:有效 类型:工作台(AC 至 DC) 电压 - 电源:110VAC,220VAC 电压 - 输出:0 ~ 30VDC,0 ~ 30VDC,0 ~ 5VDC 电流 - 输出:0 ~ 6A,0 ~ 6A,0 ~ 3A 显示类型:VFD 字符数:- 输出数:3 大小/尺寸:17.520" 长 x 8.445" 宽 x 3.472" 高(445.00mm x 214.50mm x 88.20mm) 特性:存储器,可编程,LAN,RS232,和 USB 接口 功率(W):375W 精度 - 电压表;安培计:0.03% + 10mV;0.1% + 5mA 电压调节 - 线路:0.01% + 3mV 电压调节 - 负载:0.01% + 3mV 电流调节 - 线路:0.1% + 3mA 电流调节 - 负载:0.1% + 3mA 纹波:1mV rms 重量:33 磅(15kg) 标准包装:1

913-1MM

功能描述:支架与垫片 Plastic Spcr 1mm Nylon White RoHS:否 制造商:Schurter 类型:Transipillar Spacers 长度:16 m 螺纹大小:M4 外径:10 mm 材料:Nylon with Steel 电镀:Zinc

9131RB-K

制造商:Bud Industries Inc 功能描述:A STEEL METAL HINGE, MALE SHORT LEFT HANDED HINGE, POWDER COATED IN ROYAL BLUE (

9132

制造商:Abbatron/HH Smith 功能描述:Standoff; Hex; Brass; 2-56 Thread; 3/16" OD; 1/4" Length; Full Thread 制造商:GC Electronics 功能描述:FINE LINE SOLDER 12FT 制造商:Fluke Electronics 功能描述:LOW-MELT SOLDER 制造商:GC Electronics 功能描述:Low-Melt Solder